maart 12, 2021

Nozzle: Expectations VS. Reality

How to determine a good nozzle performance? How can you see it?

Nowadays as a consumer, we are constantly looking for faster delivery, cheaper price, quick response time, in order to be able to fit in a tight budget-and schedule. Living in a digital world, it is also quite easy to have access to goods online and coming from all over the world. But getting a cheaper produced nozzle has consequences for your business.

What is the real advantage of getting an equivalent product if its quality is not as promised?

Purchasing a cheaper produced nozzle might be interesting in the short term (cheaper price and more quantity purchased) but the consequence on the long term will be costly (repetitive order, increase of maintenance, higher running cost).

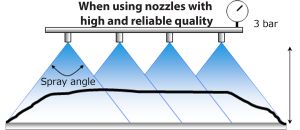

A good nozzle performance will follow the characteristics as described in the catalog. Each nozzle is designed to provide the same performance within one series. Thus, there is no variation in quality between nozzles, compared to low quality ones.

Copy products of our nozzles: high quality vs. cheap production

Here are 3 tricks to recognize a good nozzle:

- The manufacturing process of the nozzle

- Its spraying distribution

- Its spray impact

1. Manufacturing process

To produce a nozzle, there are 2 main methods (most commons):

- Machining the core material to shape it into the wanted design

- Molding the core material by injecting it in a designed mold

When producing a nozzle through injection mold, there is less margin for production errors as the initial mold determine the final shape of the nozzle. However, as soon as the nozzle need precise tooling to shape the orifice, this is where the difference between cheap and high-quality nozzle is visible.

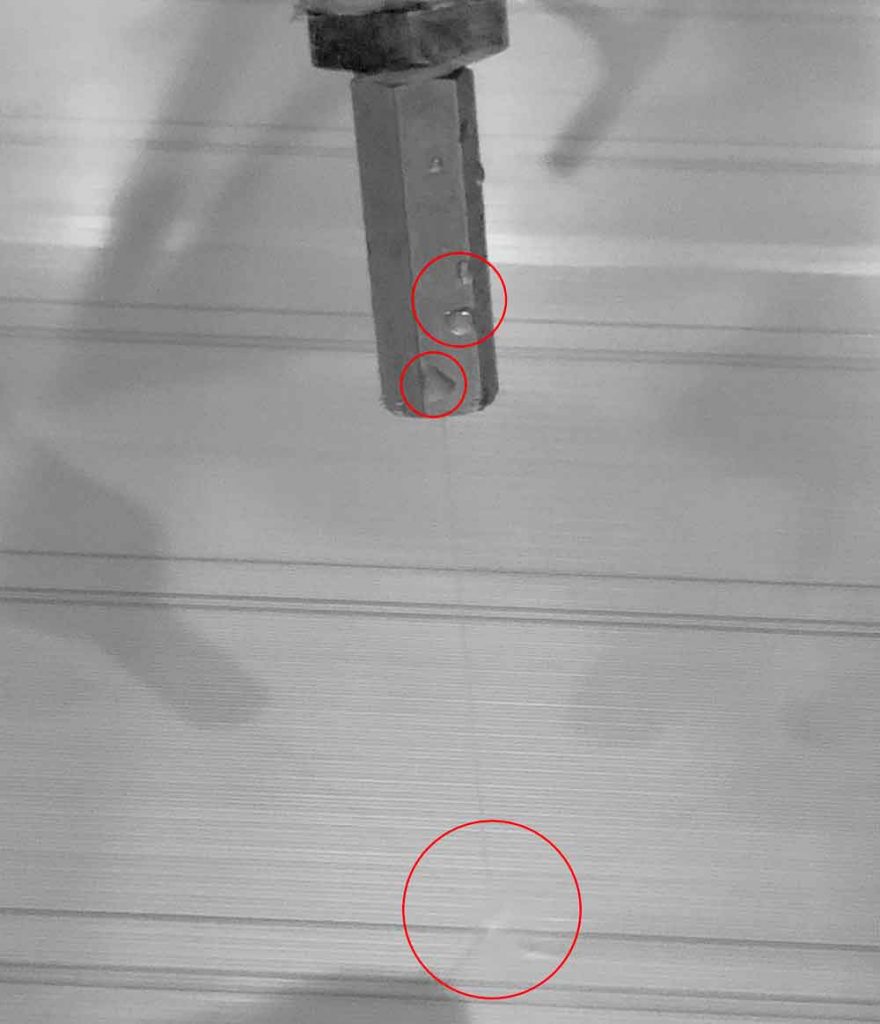

One of the visible points to recognize a cheap produced nozzle is the imprecise tooling during the manufacturing process which will result in:

- Burrs (or “teeth”) at the orifice easily noticeable, but also inside the nozzle’s structure (less visible);

- Visible streaks in the sprayed water pattern.

Burr edge

“Teeth” at the orifice

Streak side view

Streak

When spraying a nozzle with burrs, you will see streak of waters clearly visible in the water flow. This is an indication of low-quality manufacturing product made with imprecise tooling.

A spray flow with streaking will have an uneven water density and impact resulting in a larger amount of water consumption, insufficient performance and increase in running cost.

2. Spraying distribution

As a direct consequence of a cheap production quality is a poor performance. You will not reach the result expected with a disparate spray capacity (streaking) and an irregular spray angle (insufficient coverage).

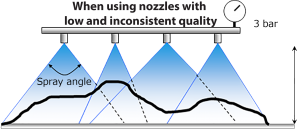

When using nozzles with low and inconsistent quality, it is also difficult for you to design an effective layout and to reach the quality of your end product as expected.

What is the consequence for you if you choose to purchase a lower unit price nozzle with unsteady performance? You will increase your cost and face a decrease in your productivity and efficiency.

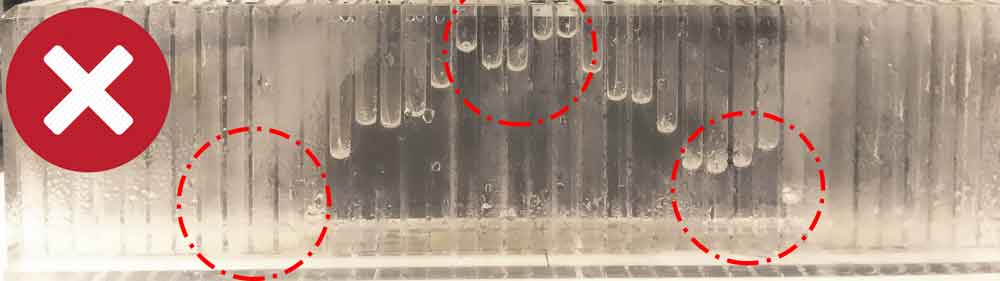

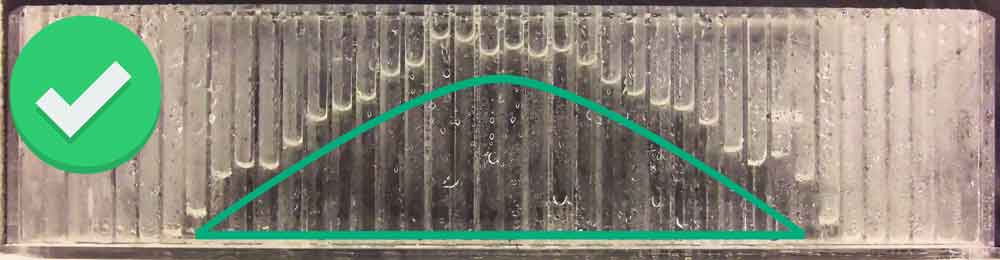

How to visually recognize a disparate distribution?

Uneven spray distribution for a mountain-shape spray

Example of a mountain-shape spray distribution

3. Spray impact

After checking the nozzle’s shape (manufacturing process) and its spraying performance, the most important aspect of the nozzle is the desired impact for the application you are looking for.

Let’s take a trimming nozzle example: It needs a straight solid jet to cut perfectly.

- So, what happen if the impact is weaker? Maybe increasing the water pressure would help. But that means increasing your running cost again.

- What happen if the nozzle drips? This consequence can simply damage the end product if the water drops disturb the production line’s quality.

Therefore, it is important to have a stronger impact with less water used for saving cost and increase productivity.

Nozzle with water drops, disturbing the spray impact of the solid stream jet

Copy products of our humidifier with lower performance on the market

When using copy products of our Dry Fog humidifier AKIMist ®, there is no guarantee of performance and it has a lower quality.

How to distinguish our Dry Fog humidifier AKIMist®”E”:

Below you can see our original Dry Fog humidifier AKIMist®”E” with 2 nozzles spraying (left picture) and with 4 nozzles (right pictures).

Here are some clues to help you recognize the copy products:

- Wrong number of nozzles: our AKIMist®”E” has a maximum of 4 nozzles

- Different color:

- Body: the green color is either more flashy or darker than our green. Or even sometimes it is not even green color…

- Nozzle: our nozzles are brown with a white top towards the orifice. If they are darker or black, it is not produced by IKEUCHI.

- Different name on the body: our product is called AKIMist® “E” (in Japanese アキミスト® “E”)

- Different logo on the body (see our logo next to our company name)